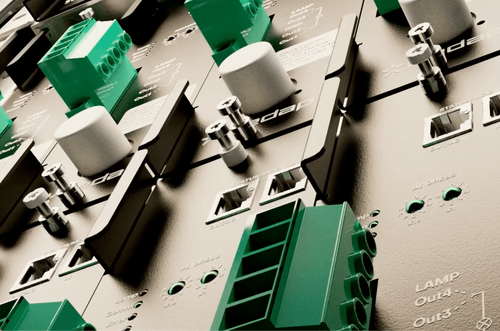

Low-pressure UV Lamp Drivers

Low–pressure UV lamp technology is up to 3x more energy efficient than medium–pressure lamp technology. Nedap’s low–pressure lamp drivers have a proven efficiency of at least 95% – lowering energy usage and cutting costs.

The perfect fit: why Nedap works for you

Proven technology:

Almost 1m UV lamp drivers installed and in use globally.

Recommended by major lamp manufacturers.

CE and UL/cUL approved.

Integrated communication intelligence.

Frequently asked questions

Frequently asked questions about powering medium pressure / polychromatic UV lamps (200-400 nm). < 1000 watt UV lamps

We’ve answered some of the questions you might have about our low-pressure UV Lamp Drivers below. If you can’t find what you’re looking for though, or would like to chat things through, please get in touch.

-

What is the average lifespan of a low-pressure UV lamp powered by Nedap’s lamp drivers?

Typical low-pressure UV-C lamps have an end-of-lamp-life (EOLL) of approximately 8,000–16,000 hours (depending on the manufacturer and lamp operation). For instance, Hereaus claims an EOLL of 9,000 hours with a 30% decline in UV intensity.

Premature lamp failure is caused by:

- Temperatures dropping too low (during dimming)

- Cables being too long

- Wrong-sized cables (skin effect)

- Resistance being too high (bad connection)

- Inferior ferrules (crimping) tools used

-

How does the temperature influence the performance of the UV lamp?

During regular operation, temperature control plays an important role in increasing lamp lifetime and efficiency. UV lamp manufacturers provide lamp ID. These are programmed in the lamp driver. Nedap lamp drivers have pre-programmed lamp parameters IDs.

-

How can you extend the lamp life?

Low-pressure lamps typically emit approximately 33% of UV output. Premature lamp failure can be caused by using the wrong ferrules and crimping tools, which causes excessive additional resistance. This can lead to overly low filament temperatures and excessive wear of the electrodes. UV lamp efficiency decreases when lamp temperatures are too low.

Nedap’s patented Additional Filament Heating technology ensures longer lamp life. Maintaining a consistent temperature provides a constant UV output for more efficient and effective operation.

-

How far can UV lamps be dimmed in a UV system?

The level of UV lamp dimming in a system depends on the following:

- UV Lamp manufacturer: Some lamps enable you to dim down to 60%. Additional filament, programmed by Nedap, allows dimming down to 30%. This massively increases UV lamp lifetime and operational efficiency.

- Lamp driver technology: Some UV lamp driver technologies offer more controls. By using a PC lamp driver tool and ModBus interface, you can set the UV lamp power, nominal lamp current, maximum lamp current, maximal lamp warmup current, and warm-up to run.

Water disinfection systems are often over-dimensioned. In water disinfection systems, lamps are dimmed down to 80%. When designing the system, the total power of the system is greater than required. Powering lamps to 100% is energy inefficient and environmentally damaging.

-

Which lamp parameters are shown by the lamp driver?

For lamp drivers which support Modbus control, information on lamp current, lamp voltage and lamp power is available.

-

Which low-pressure UV lamps are compatible with Nedap drivers?

Nedap drivers are designed to work seamlessly with all major brands of low-pressure UV lamps. Nedap smart lamp drivers have pre-programmed lamp parameters (IDs). Whenever a new UV lamp is released, we will automatically add the lamp ID to our software. This ensures integrators can immediately test it within their UV systems.

We hope we answered your question about our low-pressure UV lamp drivers here. Do not hesitate to contact us if you have any additional questions, or would like to talk about our UV lamp driver needs with an expert.

Nedap supplied the lamp drivers for the largest UV drinking water purification plant for New York City, the biggest one ever built. The plant can supply 8.3 billion liters of clean water to the more than 9 million inhabitants of New York and environs.

UV insights

Be an expert, stay an expert. Read our blog and stay up to date.