Abstract

In recent years, industries have turned to the field of operations research to help improve the efficiency of production and distribution processes. Largely absent is the application of this methodology to biological materials, such as the complex and costly procedure of human pancreas procurement and islet isolation. Pancreatic islets are used for basic science research and in a promising form of cell replacement therapy for a subset of patients afflicted with severe type 1 diabetes mellitus. Having an accurate and reliable system for cell distribution is therefore crucial. The Islet Cell Resource Center Consortium was formed in 2001 as the first and largest cooperative group of islet production and distribution facilities in the world. We previously reported on the development of a Matching Algorithm for Islet Distribution (MAID), an automated web-based tool used to optimize the distribution of human pancreatic islets by matching investigator requests to islet characteristics. This article presents an assessment of that algorithm and compares it to the manual distribution process used prior to MAID. A comparison was done using an investigator’s ratio of the number of islets received divided by the number requested pre- and post-MAID. Although the supply of islets increased between the pre- versus post-MAID period, the median received-to-requested ratio remained around 60% due to an increase in demand post-MAID. A significantly smaller variation in the received-to-requested ratio was achieved in the post- versus pre-MAID period. In particular, the undesirable outcome of providing users with more islets than requested, ranging up to four times their request, was greatly reduced through the algorithm. In conclusion, this analysis demonstrates, for the first time, the effectiveness of using an automated web-based cell distribution system to facilitate efficient and consistent delivery of human pancreatic islets by enhancing the islet matching process.

Keywords: Human islets, Algorithm, Automated cell distribution system, Islet Cell Resources (ICR), Islet equivalents (IEQs)

INTRODUCTION

In the last 30 years, the world has increasingly employed an integrated analysis approach to optimize production/distribution systems. The goal is to simultaneously consider variables associated with the planning, manufacturing, inventory tracking, and distribution process in order to generate optimization models capable of effectively and efficaciously facilitating the delivery of a product (12). The use of an integrated analysis approach has been shown to improve production efficiency in a number of industries (3,7,13). However, the application of these methods for the production and distribution of biological materials is largely absent.

Recently, we proposed an algorithm to optimize the production and distribution processes for the isolation of human pancreatic islets (10). Transplantation of these cell clusters, isolated from pancreata of deceased organ donors, represents a promising form of cell replacement therapy for a subset of patients afflicted with type 1 diabetes mellitus (1). Moreover, human pancreatic islets have been shown to be a crucial basic science research and clinical resource in diabetes research, with at least a 15% increase in the annual supply each year from 2004 to 2008, but a 25% annual increase in the demand of islets during those years, thereby exceeding the supply each year (4).

Similar to other domains, where the use of intermediate inventory is not practical or desirable (2), the production of human pancreatic islets for long-term storage and distribution purposes is not possible, as these cell clusters have a finite life span ex vivo. In addition, there is a limited supply of donated pancreata, such that careful isolation and utilization of the available islets are critical to advancing this field (5). The process of human pancreas procurement and islet isolation is highly complex, and must be conducted under extremely careful conditions to yield this valuable resource (11). Once isolated, it is crucial that the resulting islets are distributed in the most efficient and timely manner (within 24–48 h) to scientists who are able to receive and utilize these islets, thereby minimizing waste of the islet product.

The Islet Cell Resources (ICR) consortium was formulated in 2001 as a group of current Good Manufacturing Practice (cGMP) qualified production centers for the isolation of human pancreatic islets for use in clinical transplantation in type 1 diabetes, as well as the isolation and distribution of human pancreatic islets for use in basic science research regarding this life-threatening disease (6). While 14 distinct ICRs have been funded for islet production throughout the life of the consortium, over time the ICRs evolved to include eight highly productive islet distribution sites. Over the past 8 years, the number of studies approved to receive basic science islets from the ICRs grew from 23 in 2001 to 162 by the end of 2008, representing over 200 researchers and 100 institutions across the US (4). This growth in demand for islets in basic science research created new challenges in maintaining a fair and equitable distribution across all approved basic science studies. A total of 323.2 million islet equivalents (IEQs) were isolated by the ICRs from August 1, 2001 through December 31, 2008, with 68% of IEQs being used for basic science research, 30% utilized in clinical transplantation into severely diabetic patients, and a small proportion (2%) unable to be used either due to low quality/viability of the islets, lack of formal consent, or inability to distribute them in a timely manner to the investigators with approved research. From 2004 thru 2008, 2,810 shipments of islets totaling 78.6 million IEQs were distributed to the investigators for basic science research.

For the first 3 years of ICR consortium basic science islet distribution, the islet-producing centers were required to access a list of the growing number of investigators approved to receive the islets, and manually attempt to place the islets with a researcher who could utilize them at that point in time. This manual distribution method was fraught with numerous complicating factors and challenges, such as the need to appropriately match the number, quality, and type of available islets with the most suitable investigator; identifying an investigator whose lab was prepared to receive those islets within several hours; locating receiving institutions in close geographic proximity to the production site to minimize the impact of shipping on the islet viability; determining the highest priority recipient based on who had been waiting the longest for islets, or had the highest imperative study in progress; and meeting all of these challenges within a time frame that is conducive to islet quality and survival.

Due to these complex factors, the manual matching of available basic science islets to approved recipients was highly ineffective, resulting in overdistribution to certain investigators, with low or no distribution to other researchers, and poor alignment of the investigators’ needs in terms of the quantity and quality of islets required. Further, when it became difficult to readily place available basic science islets with awaiting approved researchers in a rapid time frame, the islets were either used locally, stored for a short period of time, or discarded in some cases.

In an attempt to improve the matching of available basic science islets to approved investigators, the Administrative and Bioinformatics Coordinating Center (ABCC) of the ICR Consortium proposed the development of a Matching Algorithm for Islet Distribution (MAID) (10). This algorithm was developed with input from the ICR Steering Committee, composed of the Principal Investigators and funding agency representatives for the ICR program. After development and testing, the matching algorithm was incorporated into the ICR web-based database system, also created by the ABCC and deployed in February 2007. The purpose of this article is to evaluate the effectiveness of this islet distribution algorithm across approved investigators. The ability to match islets to waiting investigators pre-versus postimplementation of MAID is presented.

MATERIALS AND METHODS

Development and Testing of the MAID Algorithm

The goal of the MAID system is to ensure efficient fair distribution of islets to ICR approved investigators, by best matching available islets to approved requestors, to: 1) optimize the receipt of islets based on waiting time and priority of the requester, and 2) more closely match the requestor’s criteria for islets than under the manual distribution process, while 3) minimizing the number of wasted islets. The core computations of the MAID system have been presented in detail elsewhere (10). Data accumulated on ICR production/distribution behavior from 2001 to 2006 were used to model patterns of islet distribution and investigator profiles, and to develop the islet matching algorithm. The MAID algorithm invokes three steps for any broadcasted production batch of islets in the following order:

Screen approved islet requestors to identify all those whose minimum criteria for islet purity, viability, and quantity would be met by the islet offer.

Rank those requests that pass the screening step, to determine the requestors who should be offered islets based on length of time waiting to receive islets and other factors for favoring the ranking score.

Select the optimal combination of requestors, using a hybrid optimization procedure of exhaustive search coupled with importance sampling, depending on the amount of available islets and the number of qualified investigators (10).

The ranking process takes into account the investigator’s waiting time, in days, with the wait time set back to 0 days any time an investigator rejects a matched islet offer targeted to his/her criteria. The weighting coefficients for favorable factors were established in consultation with the ICR Steering Committee (SC), and consisted of the following:

Multiply the priority score by: 1.1 if the islets could be delivered to the recipient within the same day; 1.1 if NIH or other peer-reviewed funding is available for the investigator’s study; 1.5 if islet purity is within 5% of the ideal purity requested by the investigators; 1.5 if islet viability is within 5% of ideal viability requested by the investigators.

Add a large bonus score if the SC designates a high-priority study and it is important to expedite islet distribution to complete this study rapidly. The priority bonus score is equal to the largest score in all qualified studies so that each high-priority study always has a higher score than all studies with standard priorities.

The optimal combination of investigators who could utilize all the islets produced with minimal waste are then offered the islets; if an investigator accepts, the islets are shipped overnight by the production ICR site to the selected investigator(s). If the islets are rejected, or there is no response from an investigator, then the algorithm is rerun and the islets are offered to the next highest ranking selected investigator(s), until all the islets are distributed.

Deployment of the MAID Algorithm Via the ICR Database System

One of the key responsibilities of the ABCC was to develop a web-based database system for the ICRs, to allow them to remotely enter high-quality data detailing the process and the resulting characteristics of their islet isolation process for every batch processed. These data are invaluable to assess the patterns and results of islet processing among the ICRs nationwide, and to correlate islet isolation data with results of basic science research and clinical transplantation for type 1 diabetes.

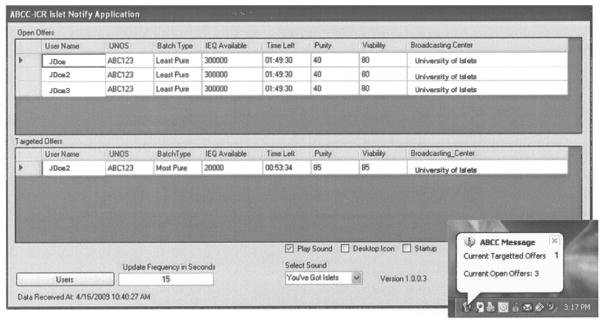

Once developed and thoroughly tested, MAID was incorporated into the ICR database system, to support: 1) broadcasting islets available for approved investigators via the Internet, with automated immediate notification to investigators when they have been selected to receive an islet offer; 2) online investigator response regarding their acceptance or rejection of the islet offer; 3) online entry of islet shipment data, and automated shipping form creation for tracking islet shipments by the ABCC; and 4) direct online access to user feedback forms completed by the islet recipients after islet receipt and viewable by the islet production centers. Approved investigators are notified of available islets with automated messages via email, pages, and cell phone text messages. To further ensure that the offer will be noticed, an islet offer “widget” that automatically pops up on the selected investigator’s desktop is available to all investigators for download (Fig. 1). This widget displays islet parameters such as available IEQ amount, batch type, time left, purity, viability, and broadcasting center. Full data on the islet offers, acceptance/rejection, and shipments are stored in the ICR database for further analysis and evaluation.

Figure 1.

Online web-based islet offer broadcasts and notification widget. In this example, the Islet Notification Service (INS) widget is being used by hypothetical user John Doe to monitor his three approved studies (usernames JDoe, JDoe2, and JDoe3). All three studies were contacted for the open offer corresponding to the least pure islet fraction of 40% purity from the hypothetical center, University of Islets. In addition, the second study (username JDoe2) also qualified for a targeted offer corresponding to the most pure islet fraction (85% purity). The INS displays 1 h, 49 min, and 30 s remaining for the open offers and 53 min and 34 s remaining for the targeted offer.

Islet Distribution Mechanisms of MAID

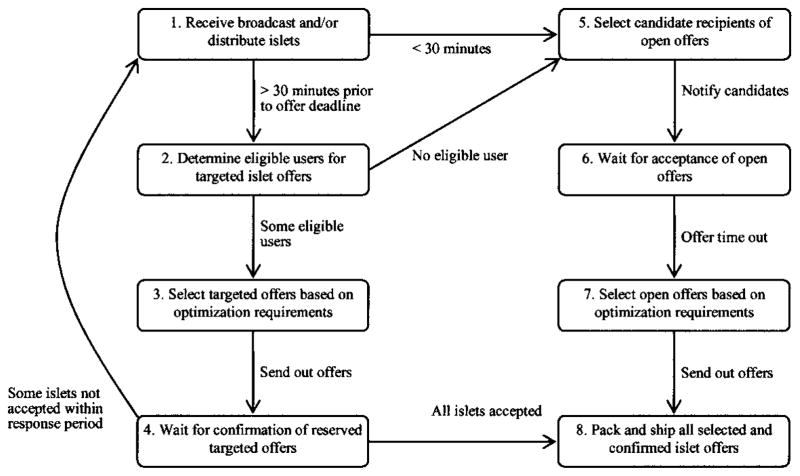

Two distinct types of offers are administered by MAID to promote the placement of all islets offered by the participating islet production centers (Fig. 2). In the first type of offer, targeted offers are created by MAID when: a) there are one or more eligible investigators whose requested islet criteria match the parameters of the available islets, and b) there are more than 30 min remaining before the shipment deadline established by the ICR center. Targeted offers are noncompetitive; the recipient of a targeted offer has been predetermined to be part of the optimal match and thus has an inherent priority to receive the offered islets, if they accept the offer. Islets are reserved for individual investigators for a duration of time equal to half of the remaining time prior to the shipment deadline, set by the islet production site at the time of broadcasting the islet availability (up to the last 0.5 h). During this time, each offer recipient will have the opportunity to review the available isolation data and accept or reject the offer. If one or more of the targeted offer recipients rejects or fails to respond to the targeted offer, MAID will reevaluate the two targeted offer criteria above, and send additional targeted offers, or proceed to the next offer type if necessary.

Figure 2.

Islet allocation process via targeted and open islet offers.

When one or both of the targeted offer criteria listed above are false, MAID creates open offers as the second type of offer. Open offers are competitive; the islets are not reserved for particular investigators. Instead, more than one investigator is notified of the same available islets, and all are given the opportunity to accept the open offer. Once the shipment deadline has been reached and the offer is closed to additional offers, MAID prioritizes the investigators that accepted the open offer using optimization techniques similar to those used to determine priority for targeted offers. As a result of this competitive nature, it is possible that one or more of the investigators accepting an open offer will receive a lower priority score than the other accepting investigators, and therefore be denied by the system, if there is an insufficient sum of islets to meet all accepted offers. In this instance, the investigators with the optimal open offer score are notified by MAID that they have been selected to receive the islets from the open offer, and the investigators with the suboptimal open offer scores are notified that they were not confirmed to receive islets from this offer. Open offers provide the valuable utility of contacting a large group of investigators for the purpose of placing all available islets before the islet isolation offer deadline. The number of open offer recipients is proportional to the number of available islets to ensure that a sufficient, but not excessive, number of investigators are contacted to place the remaining islets.

Evaluating the Effectiveness of MAID

We utilized data gathered pre- versus postdeployment of the automated algorithm, to determine whether the deployment of MAID had a positive impact on the ability of the ICRs to effectively place their isolated islets with investigators requiring such islets for research or transplantation. Over a 43-month period, from February 2004 to August 2007, a total of 1,296 shipments consisting of 39,369,909 IEQs were distributed pre-MAID implementation (63 shipments distributed using the manual process during the first 6 months of initial deployment of MAID were also included). During a 22-month period, from March 2007 to December 2008, 1,514 shipments with a total of 39,314,776 IEQs were distributed post-MAID implementation. Across both time periods these shipments were made to 154 requesting studies from 14 ICR centers. There were 110 active studies in the pre-MAID period, and 118 active in the post-MAID period; 74 of the studies active during both periods, and therefore these studies were considered in both time periods.

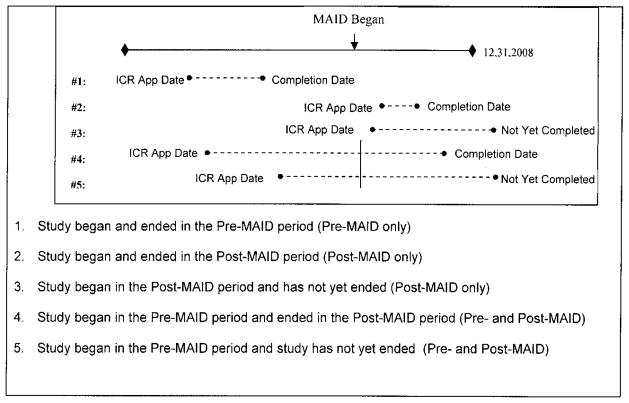

To determine the effectiveness of the algorithm in distributing islets for approved studies, a standard measurement was created to compare successful placement of islets pre- versus postalgorithm implementation. The measurement was a ratio of received-to-requested islets, calculated for each approved study of islets. Received islets were tracked manually by the ABCC pre-MAID, and via the web-based system postimplementation. There were five possible scenarios of a study’s active status pre- and post-MAID deployment, as shown in Figure 3. The scenarios included studies that either only took place in the pre-MAID period, only in the post- MAID period, or in both periods. Received-to-requested ratios were calculated for each period a study was approved. Eight studies were only conditionally approved ICR islet recipients and were therefore excluded from the analysis.

Figure 3.

Possible scenarios for calculation of the received-to-requested ratio pre- and postimplementation of matching algorithm for islet distribution (MAID).

To determine how the average distributions changed between the pre- and post-MAID periods we analyzed the number of monthly shipments, the number of IEQs shipped per month, and type of islets shipped. Shipments made after the implementation of MAID that did not use the system were excluded from the monthly values. Islet type was determined by high quality (viability and purity over 80%), medium quality (viability and purity between 50% and 80%), and low quality (either viability or purity less than 50% or unknown).

Box plots were created for the received-to-requested ratio pre- versus post-MAID, and the median and range of the ratios were calculated. Ratio values were highly skewed and not normally distributed; therefore, the Wilcoxon rank sum test was used to test for a difference in the received-to-requested ratio between pre- versus post-MAID time periods (9). However, because the average received-to-requested ratio is a measure of supply and demand, it is not a great measure of how MAID may have improved islet distribution; we were therefore more interested in whether the variability of the received-to-requested ratios differed between the two time periods. The Levene’s Test of Homogeneity was used to determine if the variability of ratios was similar between the two time periods (8). In addition, the ratios were categorized into intervals, and the percent of studies falling into each of the ratio intervals was calculated. The chi-square test of association was applied to evaluate whether there was an association between the received-to-requested ratio pre- and postalgorithm implementation. We recognize there was clustering present due to investigators having multiple studies; therefore, we also ran a generalized estimating equation (GEE) analysis clustering studies by investigator and adjusting for the amount of requested islets (<3,000,000 or ≥3,000,000 islets) to test homogeneity of the variability. Similarly, we also ran the GEE analysis to test the association of the received-to-requested ratio groups pre- and post-MAID implementation. Because these analyses yielded similar results, we are reporting the original methods for ease of interpretation.

Although the breadth of the data is limited during the prealgorithm period, advances in data collection related to the implementation of the algorithm allow for more dynamic analyses during the post-MAID period. With this additional data during the postalgorithm period, we further analyzed possible reasons for any observed differences in the received-to-requested ratio. Post-MAID ratios were evaluated against two factors: total amount of approved islets needed for the study’s research (<3,000,000 IEQs vs. ≥3,000,000 IEQs), and an acceptance rate (i.e., the proportion of offers a study agreed to accept for a given study: 0–24%, 25–49%, or 50–100%). The Wilcoxon Rank Sum test was used to determine whether the ratio of received-to-requested islets differed depending on the total amount of islets approved for a study. A Spearman correlation coefficient was calculated to determine if there was a significant linear trend between the level of accepted offers and the received-to-requested ratio (9). All analyses used the SAS statistical software (version 9.1; SAS Institute, Cary, NC).

RESULTS

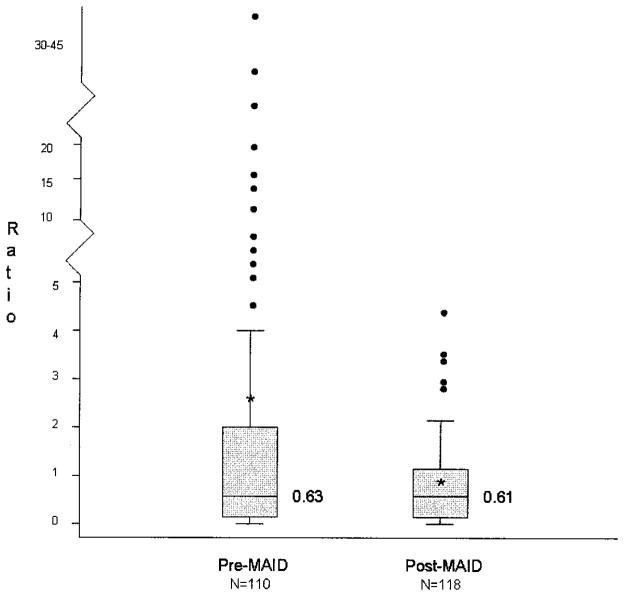

The average production of islet distribution activities was increased in pre- versus post-MAID as shown by both number of monthly shipments made and monthly IEQs shipped (Table 1). The number of monthly shipments increased from 33 to 69 and the number of IEQs shipped per month increased from 1 million to 1.8 million. High-quality islets were more frequently distributed in post-MAID compared to the pre-MAID period. The box plots for the pre- versus post-MAID period are shown in Figure 4. It can be seen that while production increased, so too did demand, such that the median received-to-requested ratios were almost identical pre- versus postimplementation of MAID (0.63 vs. 0.61, respectively, p = 0.13), indicating that in both time periods approximately two thirds of the desired islets could be delivered to the requesting investigators. It can also be seen that there is a significant difference in the variability of the received-to-requested ratios pre- versus post-implementation (p = 0.04) (Fig. 4). Pre-MAID ratios varied from no islets received to 45.4 times the requested amount, while post-MAID these ratios had greatly reduced variability with a range from 0 to 4.4.

Table 1.

Summary of Pre- and Post-Web Deployment of the Matching Algorithm for Islet Distribution (MAID)

| Variable | Pre-Web | Post-Web |

|---|---|---|

| Monthly shipments* | 33.3 ± 20.9 (3, 82) | 69.0 ± 29.7 (21, 128) |

| Monthly shipped IEQs* (106) | 1.0 ± 0.8 (0.05, 3.3) | 1.8 ± 0.7 (0.4, 3.4) |

| Shipments by purity & viability | ||

| Both 80% or higher | 553 (43%) | 765 (51%) |

| Both 50% or higher | 218 (17%) | 341 (22%) |

| Either below 50%, or unknown | 525 (40%) | 408 (27%) |

The reported statistics are mean ± SD (range), frequency (%).

Note that 63 (5% of pre-MAID) shipments distributed using manual process were excluded from the pre-web monthly shipments and monthly shipped IEQs because they were made after the inception of the MAID system.

Figure 4.

Distribution of received-to-requested islet ratios of pre- versus post-MAID for all approved studies (N = 154). Variability demonstrated in the box plots was significantly different between the pre-MAID and post-MAID period using Levene’s Test for Homogeneity (p = 0.04).

The proportions of the received-to-requested ratio by intervals are shown in Table 2. A very similar proportion of studies received less than the desired quantities (up to 75% of their requests) for 54% of studies in the pre-MAID period, and 58% of studies in the post-MAID period, reflecting that only two thirds of the demand could be fully met by production in either time frame. The proportion of studies in the most desirable received-to-requested ratio range (from 76% to 150% of their desired amount) more than doubled after implementation of the islet distribution algorithm, from 13% pre-MAID to 31% post-MAID. Additionally, the undesirable outcome of providing more islets than required (from 151% to over 400%) was cut by two thirds through implementation of the algorithm, with 33% of studies in this oversupplied range pre-MAID, and only 11% post-MAID. The association between implementing the algorithm and the ratio of received-to-requested was statistically significant by chi-square test (p = 0.001).

Table 2.

Frequency of Received-to-Requested Islet Ratios by Pre- Versus Post-MAID for All Approved Studies (N = 154)

| Interpretation of Ratio | Ratio | Pre-Website Frequency (N = 110) | Post-Website Frequency (N = 118) |

|---|---|---|---|

| Less Desirable—under supplied | 0.00 | 12 | 13 |

| >0.00–0.25 | 19 | 19 | |

| >0.25–0.50 | 16 | 19 | |

| >0.50–0.75 | 13 | 18 | |

| Percentage | 54% | 58% | |

| Desirable—supply similar to request | >0.75–1.00 | 7 | 18 |

| >1.00–1.50 | 7 | 18 | |

| Percentage | 13% | 31% | |

| Less desirable—over supplied | >1.50–2.00 | 7 | 8 |

| >2.00–3.00 | 11 | 2 | |

| >3.00–4.00 | 6 | 2 | |

| >4.00 | 12 | 1 |

Chi-square test of association was performed to determine if there is an association between received-to-requested ratio and time period (p = 0.001). “Interpretation of Ratio” refers to the categorization of islet supply based on the balance between distribution efficiency, fairness among islet recipients, and feasibility of research resulting from the available supply of islets.

Table 3 summarizes our investigation into possible causes of a low received-to-requested ratio postimplementation of MAID using the enriched data available postimplementation of MAID. As could be anticipated, studies that desire a very large amount of islets (>3,000,000 IEQs) were significantly less likely to receive their desired amount, with a median received-to-requested ratio of 0.33 for those requiring greater than 3 million islets, versus a more desirable ratio of 0.71 of their needs for studies requesting smaller amounts (p = 0.02).

Table 3.

Evaluation of Factors Associated With Received-to-Requested Islet Ratio Postimplementation of MAID

| Variable | N | Median Received-to-Requested Ratio | 25th–75th Percentile | p-Value |

|---|---|---|---|---|

| Total approved islets (N = 117 studies)* | ||||

| Total approved islets <3 million | 98 | 0.71 | 0.26–1.06 | 0.02 |

| Total approved islets ≥3 million | 19 | 0.33 | 0.12–0.55 | |

| Acceptance rate (N = 107 studies)† | ||||

| Accepted 0–24% of offers | 53 | 0.50 | 0.18–0.88 | <0.0001 |

| Accepted 25–49% of offers | 40 | 0.75 | 0.42–1.10 | |

| Accepted 50–100% of offers | 14 | 0.85 | 0.70–1.20 | |

N = 117 and not 118 because one study did not provide a value for total islets. The p-value was calculated using Wilcoxon rank sum test.

Only studies that received open and/or target offers were included in analysis. The p-value was calculated by Spearman correlation.

In addition, the influence of a study’s acceptance rate of both targeted and open offers was evaluated for their ratio of received islets. There was a linear trend observed, with those accepting only 0–24% of offers having the lowest median received-to-requested ratio of 0.50, those accepting 25–49% of offers having a more favorable median of 0.75, and those accepting 50% or more of offers having a highly desirable median ratio of 0.85 (p < 0.0001).

DISCUSSION

Before the development of an automated method for matching investigator criteria to islets available for distribution, islet isolation centers needed to manually match the islets to a list of investigators interested in obtaining them. This was often a time-consuming process, and resulted in undistributed or wasted islets or an oversupply to the same requesters. To ensure the most efficient distribution of islets, the ABCC implemented an automated matching algorithm to aid in islet distribution. With the experience of close to 2 years of islet distributions using the automated algorithm, the authors have evaluated its impact on successfully placing islets with approved investigators who request them.

This evaluation of our automated method for matching scientists requiring islets with the islets produced by the ICRs nationwide demonstrates the efficiency of an integrated analysis approach for a production distribution system involving human biological materials. We have shown that the MAID system greatly improved this matching process. The median received-to-requested islet ratio did not differ between pre- and post-MAID implementation, reflecting the continued demand of islets exceeding the amount of available islets supplied. The variability in how many islets the investigators received was substantially reduced, indicating a more fair distribution of islets in accordance with the requests. Fewer investigators received very low proportions of their needed islets, and there were many fewer instances of oversupplying some investigators, to the detriment of the others waiting for islets.

The fact that, in both time periods, only about two thirds of the desired islets nationwide could be supplied is a reflection of the supply-to-demand issue across the nation. The demand outstrips the supply due to many factors: the complex process in producing high-quality islets, establishing and maintaining a cGMP-approved infrastructure, hiring and training technical staff, and obtaining viable pancreata for harvesting. Solutions to these constraints need to be reached in order to fully satisfy the diabetes research and transplantation needs for islets.

Our evaluation also showed that the optimal received-to-requested ratio of 1.00 is achievable. If the total amount of islets required is in a practical range of less than 3,000,000 islets, the supply for such studies can be successfully met by using the MAID system to match their requests with the islet isolations. However, as seen, certain experiments may require the use of a greater number of islets than others (4). Hence, this factor may not be modifiable in experiments requiring such a large amount of islets.

An influencing factor that is under the control of the investigators requesting islets is their acceptance rate when islets are offered to them via the automated MAID system. If the investigators respond to these offers and accept them at least 25–49% of the time, a very reasonable received-to-requested ratio of 0.75 offers can be achieved. If the investigators accept the islet offers even half of the time this ratio jumps to 0.85 of their desired islet amount. This illustrates the success of the MAID algorithm in properly allocating supply even in environments where demand greatly exceeds supply. Although the received-to-requested ratio can be affected by a number of factors outside the investigators’ control, such as production levels and quality of islets, the MAID algorithm successfully accounts for all of these factors. When investigators respond in a timely manner to the offers provided, MAID achieves a reduction in extreme values of the received-to-requested ratio. Further, the MAID algorithm closely matches targeted offer characteristics to investigator needs in the post-MAID period. In addition, postimplementation of MAID the algorithm was able to place all of islets in an isolation batch 93% of the time, and placed at least 75% of the islets in 96% of the batches offered for distribution. While this information was not available pre-MAID, our experience suggests that the pre-MAID distributions were not as closely matched to investigator requests, or placed as successfully as the post-MAID distributions.

This study has a few limitations. The amount of detailed information is much richer postimplementation of MAID than preimplantation, when only manual records of islet shipments (and not offers) were kept in this earlier time period. Therefore, while we could identify some conditional factors captured through the data system that might influence successful placement of islets, we did not have this information recorded pre-MAID. We were also unable to determine if MAID was successful in reducing the number of unused islets because of the lack of information pre-MAID. To avoid bias in one time period or another such investigators were included in both time periods; however, this could alter the results slightly.

The supply-to-demand ratio remains the largest problem (4). If this could be resolved, all the requests for islets to speed diabetes research could potentially be resolved. In the meantime, this evaluation has demonstrated that the MAID automated islet distribution system greatly enhances the islet matching process, and delivers closer to the desired amount of islets without wasting or oversupplying them. Therefore, we will continue to rely upon and continually enhance the MAID system. Such a system could potentially be modified to fit other matching problems in the scientific world in future, such as organ donors.

Acknowledgments

Islet distribution data were obtained through the Islet Cell Resource Center (ICR) Basic Science Human Islet Distribution Program. Helpful discussions about the rules for the algorithm were provided by ICR Steering Committee members. The authors are equally grateful to all of the ICR principal investigators and staff members at each contributing laboratory for providing guidance in the development of the algorithm and feedback during deployment of the ICR islet allocation system. In addition, special thanks is given to Martha Antler for assistance in collecting some of the data used in this manuscript. This work was funded by the cooperative efforts of the National Center for Research Resources (NCRR) and the National Institute of Diabetes and Digestive and Kidney Diseases, a component of the US National Institutes of Health (NIH) in conjunction with the generous contributions of the Juvenile Diabetes Research Foundation. Drs. Niland and Qian, Messrs. Cravens and Kaddis, and Mss. Stiller and Sowinski were supported by grant U42 RRR017673 (J.C.N) from the NCRR.

References

- 1.Alejandro R, Barton FB, Hering BJ, Wease S. Update from the Collaborative Islet Transplant Registry. Transplantation. 2008;86:1783–1788. doi: 10.1097/TP.0b013e3181913f6a. [DOI] [PubMed] [Google Scholar]

- 2.Chen ZL, Vairaktarakis GL. Integrated scheduling of production and distribution operations. Manag Sci. 2005;51:614–628. [Google Scholar]

- 3.Cohen MA, Lee HL. Strategic analysis of integrated production-distribution systems: Models and methods. Oper Res. 1988;36:216–228. [Google Scholar]

- 4.Kaddis JS, Olack BJ, Sowinski J, Contreras JL, Niland JC. Human pancreatic islets and diabetes research. JAMA. 2009;301:1580–1587. doi: 10.1001/jama.2009.482. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Kandaswamy R, Sutherland DE. Pancreas versus islet transplantation in diabetes mellitus: How to allocate deceased donor pancreata? Transplant Proc. 2006;38:365–367. doi: 10.1016/j.transproceed.2006.01.005. [DOI] [PubMed] [Google Scholar]

- 6.Knazek RA. The human pancreatic islet cell resource consortium. Diabetes Technol Ther. 2002;4:551–552. doi: 10.1089/152091502760306652. [DOI] [PubMed] [Google Scholar]

- 7.Lee YH, Kim SH. Production–distribution planning in supply chain considering capacity constraints. Comput Ind Eng. 2002;43:169–190. [Google Scholar]

- 8.Montgomery D. Design and analysis of experiments. 5. New York: Wiley; 2001. [Google Scholar]

- 9.Pagana M, Gauvreau K. Principles of biostatistics. 2. Pacific Grove, CA: Duxbury; 2000. [Google Scholar]

- 10.Qian D, Kaddis J, Niland JC. A matching algorithm for the distribution of human pancreatic islets. Comput Statist Data Anal. 2007;51:5494–5506. doi: 10.1016/j.csda.2007.02.030. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Ricordi C, Strom TM. Clinical islet transplantation: Advances and immunological challenges. Nat Rev Immunol. 2004;4:259–268. doi: 10.1038/nri1332. [DOI] [PubMed] [Google Scholar]

- 12.Sarmiento AM, Nagi R. A review of integrated analysis of production distribution systems. IIE Trans. 1999;31:1061–1074. [Google Scholar]

- 13.Vidal CJ, Goetschalckx M. Strategic production-distribution models: A critical review with emphasis on global supply chain models. Eur J Oper Res. 1997;98:1–18. [Google Scholar]