Abstract

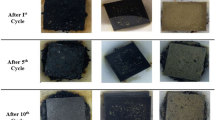

Surface deterioration by corrosion is one of the complications associated with ageing facilities and components especially under some service environments. This study was designed to investigate the enhancement in the corrosion and hardness properties of UNS G10150 steel laser alloyed with three different premixed compositions of Zn-Sn binary powders using a 4.4 KW continuous wave (CW) Rofin Sinar Nd:YAG laser processing system. The steel alloyed samples were cut to corrosion coupons, immersed in hydrochloric acid (1M HCl) solution at 30 °C using an electrochemical technique and investigated for their corrosion behaviour. The morphologies and microstructures of the developed coatings and uncoated samples were characterized by an Optic Nikon Optical microscope (OPM) and a scanning electron microscope (SEM/EDS). Moreover, a X-ray diffractometer (XRD) was used to identify the phases present. An improvement of 2.5-times the hardness of the steel substrate was achieved in A1(0.8) which may be attributed to the fine microstructure, dislocations and the high degree of saturation of solid solution brought by the high scanning speed. At a scanning speed of 0.8 m/min, sample A1 exhibited the highest polarization resistance Rp (3163000 O.cm2), lowest corrosion current density icorr (7.95X10-8A/cm2), with a lowest corrosion rate Cr (0.000924 mm/year) in 1M HCl solution. The polarization resistance Rp (3163000 O.cm2) is 392,281-times the polarization of the UNS G10150 steel substrate with a 99.9994 % reduction in the corrosion rate.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.References

Tao Z, Zhang S, Li W, Hou B (2009) The role of metal cations in improving the inhibitive performance of hexamine on the corrosion of steel in hydrochloric acid solution. Corros Sci 51:2588–2595

Singh AK (2012) Inhibition of mild steel corrosion in hydrochloric acid solution by 3-(4-((Z)-Indolin-3-ylideneamino) phenylimi-no)indolin-2-one. Ind Eng Chem Res 51:3215–3223

Ahamad I, Prasad R, Quraishi MA (2010) Adsorption and inhibitive properties of some new Mannich bases of Isatin derivatives on corrosion of mild steel in acidic media. Corros Sci 52:1472–1481

Hosseini MG, Ashassi-Sorkhabi H, Ghiasvand H (2008) Electrochemical Studies of Zn–Ni Alloy Coatings from Non-cyanide Alkaline Bath Containing Titrate as Complexing Agent. Surf Coat Technol 202:2897–2904

Abdallah M (2003) Corrosion behaviour of 304 stainless steel in sulphuric acid solutions and its inhibition by some substituted pyrazolones. Mater Chem Phys 82:786–792

Sathiyanarayana S, Marikkannu C, Palaniswamy N (2005) Corrosion inhibition effect of tetramines for mild steel in 1 M HCl. Appl Surf Sci 241:477–484

Fouda AS, Abdallah M, Al-Ashrey SM, Abdel-Fattah AA (2010) Some crown ethers as inhibitors for corrosion of stainless steel type 430 aqueous solutions. Desalination 250 :538–543

Roy P, Pal A, Sukul D (2014) Origin of the synergistic effect between polysaccharide and thiourea towards adsorption and corrosion inhibition for mild steel in sulphuric acid. RSC Adv 4:10607–10613

Omotosho OA, Ajayi OO, Fayomi OS, Ifepe VO (2010) Assessing the deterioration behavior of mild steel in 2M sulphuric acid using bambusa glauscescens. Int J Appl Eng Res D 2(2):406–418

Zhang J, Sun C, Yu Z, Cheng J, Li W, Duan J (2014) The performance of Zinc sacrificial anode in simulating marine fouling environment. Int J Electrochem Sci 9:5712–5721

Bobic B, Mitrovic S, Babic M, Bobic I (2010) Corrosion of Metal-matrix Composites with Aluminium Alloy Substrate. Tribol Ind 32:3–11

Popoola API, Fayomi OSI, Popoola OM (2012) Electrochemical and Mechanical Properties of Mild Steel Electro-plated with Zn- Al. Int J Electrochem Sci 7:4898–4917

Fontenay F (2002) Electrodeposited zinc and zinc alloy coatings and their corrosion resistance. Part 1, Galvanotechnik 93:2534–2541

Guaus E, Torrent-Burgues J (2003) Tin-Zinc electrodeposition from sulphate-gluconate baths. J Electroanal Chem 549: 25–36

Blunden SJ, Killmeyer AJ (1991) Sn-Zn alloy electroplates outperform cadmium deposits. Adv Mater Processes 140(6):37–39

Budman E, McCoy M (1995) Tin-Zinc plating. Met Finish 93(9):10–11

Budman E, Stevens D (1998) Tin-Zinc plating. Trans Inst Met Finish 76(3):B34

Schario DA, Klingenberg ML, Brooman EW (1996) Abstracts of the 190th Meeting of the Electrochemical Society, 96-2(309). The Electrochemical Society, Pennington

Pushpavanaman M (2000) Bull Electrochem 16:559–566

Popesco E, Tournier R (1999) Le zingage electrolytique pratique, Medro Edition

Kwok CT, Cheng FT, Man HC (2006) Cavitation Erosion and Corrosion Behaviours of Laser-aluminized Mild Steel. J Surf Coat Technol 200:3544–3552

Dobrzanski LA, Piec M, Bonek M, Jonda E, Klimpel A (2007) Mechanical and tribological properties of the laser alloyed surface coatings. J Achiev Mater Manuf Eng 20(1–2):235–238

Fagagnolo JB, Rodrigues AV, Lima MSF, Amigo V, Caram R (2013) A novel proposal to manipulate the properties of titanium parts by laser alloying. J Script Mater 68:471–474

Adebiyi DI, Popoola API, Pityana SL (2014) Microstructural evolution at the overlap zones of 12Cr martensitic stainless steel laser alloyed with TiC. J Opt Laser Technol 61:15–23

Wei L, Huijun Y, Chuanzhong C, Diangang W, Fei W (2013) Microstructures of hard coatings deposited on titanium alloys by laser alloying technique. J Surf Rev Lett 20:1–6

Yakovlev A, Bertrand P, Smurov I (2004) Laser cladding of wear resistant metal matrix composite coatings. Thin Solid Films 453:133–138

Poulon-Quintina A, Watanabe I, Bertranda C, Watanabe E (2012) Microstructure and mechanical properties of surface treated cast titanium with Nd:YAG laser. Dent Mater 28:945–951

Zhou R, Sun GF, Chen KK, Tong YQ (2014) Effect of tempering on microstructure mechanical properties of cast iron rolls laser alloyed with C-B-W-Cr. In: Proceedings of the global conference on polymer and composite materials

Sugioka K, Cheng Y (2014) Ultrafast lasers-reliable tools for advanced materials processing. Light Sci Appl:3–30

Oakes G, West JM (1969) Influence of Thiourea on the Dissolution of Mild Steel in Strong Hydrochloric Acid. Br Corros J 4 :66–73

Gad Allah AG, Nassif N, Mikhail T (1992) Effect of temperature on the corrosion behaviour of helwan steel in acid chloride solutions. Annali di Chimica 82:49–71

Ben Hmamou D, Salghi R, Zarrouk A, Al-Deyab SS, Zarrok H, Hammouti B, Errami E (2012) Verbena extract: an efficient inhibitor of C38 steel corrosion in hydrochloric acid. Int J Electrochem Sci 7:6234–6246

Morad MS, Kamal El-dean AM (2006) 22’-Dithiobis(3-cyano-4,6-dimethylpyridine): A new class of acid corrosion inhibitors for mild steel. Corros Sci 48:3398–3412

Tebbji K, Oudda H, Hammouti B, Benkaddour M, El Kodadi M, Malek F, Ramdani A (2005) Inhibitive action of two bipyrazolic isomers towards corrosion of steel in 1 M HCl. Appl Surf Sci 241:326–334

Yurt A, Balaban A, Kandemir SU, Bereket G, Erk B (2004) Investigation on some Schiff bases as HCl corrosion inhibitors for carbon steel. Mater Chem Phys 85:420–426

Abdullah M, Fouda AS, Shama SA, Afifi EA (2008) Azodyes as Corrosion Inhibitors for Dissolution of C-steel in Hydrochloric Acid Solution. Afr J Pure Appl Chem 9:083–091

Loto RT (2013) Pitting Corrosion evaluation of Austenitic Stainless Steel Type 304 in Acid and Chloride Media. J Mater Envir Sci 4(4):448–459

Leckie HP, Uhlig HH (1262) Pitting Corrosion. J Electrochem Soc:113

Galvele JR (1981) Forms of Corrosion. Corros Soc 21:551

Japtap RN, Patil PP, Hassan SZ (2008) Effect of zinc oxide in combating corrosion in zinc-rich primer. Prog Org Coat 63:389–394

Fattah-alhossein A, Alemi MH, Banael S (2011) Diffusivity of Point Defects in the Passive Film on Stainless Steel. Int J Electrochem:6. doi:10.4061/2011/968512

Dubent S, De Petris-Wery M, Saurat M, Ayedi HF (2007) Composition control of Tin-Zinc electrodeposits through means of experimental strategies. Mater Chem Phys 104:146–152

Rahman MJ, Sen SR, Moniruzzaman M, Shorowordi KM (2009) Morphology and Properties of Electrodeposited Zn-Ni Alloy Coatings on Mild Steel. J Mech Eng Trans Mech Eng Div Inst Eng 40:9–12

Popoola API, Pityana SL, Popoola OM (2011) Laser deposition of (Cu + Mo) alloying reinforcements on AA1200 substrate for corrosion improvement. Int J Electrochem Sci 6:5038–5051

Hosking NC, Ström MA, Shipway PH, Rudd CD (2007) Corrosion resistance of zinc– magnesium coated steel. Corros Sci 49:3669–3695

Qu Q, Yan C, Wan Y, Cao C (2012) Effects of NaCl and SO2 on the initial atmospheric corrosion of zinc. Corros Sci 44(12):2789–2803

Falk T, Svensson JE, Johansson LG (1998) The Influence of CO2 and NaCl on the atmospheric corrosion of zinc - A laboratory study. J Electrochem Soc 145:2993

Praveen BM, Venkatesha TV (2008) Electrodeposition and Properties of Zn-nanosized TiO2 Composite Coatings. Appl Surf Sci 254(8):2418–2424

Zivica V (2002) Electrochemical activity of heavy metal oxides in the process of chloride induced corrosion of steel reinforcement. Bull Mater Sci 25(5):371–374

Felui S, Barajas R, Bastidas J, Morcillo M (1989) Mechanism of cathodic protection of zinc-rich paints by electrochemical impedance spectroscopy. J Coat Technol 61(775):71–76

Grigoryan RA (2001) High-temperature synthesis with plasma heating and investigation of complex oxides on the basis of zinc orthostannate. Cand Sci (Chem) Dissertation, Chernogolovka: Institute of Structural Macro-Kinetics and Materials Science RAS

Panakh-zade CA, Amirdzhanova TB, Kh. Kurbanov T (1985) Synthesis and properties of Cd2xZn2-2xSnO4. ZhNKh 30(10):517–524

Hwang D, Jin J, Lee H, Kim H, Ching H, Kim D, Jang S, Kim D (2014) Hierarchically structured Zn2SnO4 nanobeads for high-efficiency dye-sensitized solar cells. Sci Rep 4:1–7

Zhang XG (1996) Corrosion and Electrochemistry of Zinc. Plenum Press, New York, p 157

Hernandez-Alvarado LA, Hernandez LS, Rodriguez-Reyna SL (2012) Evaluation of Corrosion Behavior of Galvanized Steel Treated with Conventional Conversion Coatings and a Chromate-Free Organic Inhibitor. Int J Cor 2012:1–9

Hassan HH (2001) Corrosion behaviour of zinc in sodium perchlorate solutions. Appl Surf Sci 174:201–209

Hoar TP, Mears D, Rothwell G (1965). Corros Sci 5:279–289

Li D, Liu PCC (2008) Corrosion characterization of tin–lead and lead free solders in 3.5 wt.% NaCl solution. Corros Sci 50:995–1004

Rosalbino F, Angelini E, Zanicchi G, Carlini R, Marazza R (2009) Electrochemical Corrosion Study of Sn–3Ag–3Cu Solder Alloy in NaCl solution. Electrochim Acta 54:7231–7237

Tsao LC, Lo TT, Peng SF, Chang SY (2010) Electrochemical behavior of a new Sn3.5Ag0.5Cu composite solder. In: Proceedings of 11th International Conference on Electronic Packaging Technology & High Density Packaging

Fayomi OSI, Abdulwahab M, Popoola API (2013) Properties evaluation of ternary surfactant-induced Zn -Ni -Al2O3 films on mild steel by electrolytic chemical deposition. J Ovonic Res 9(5):123–132

Rahman MJ, Sen SR, Moniruzzamanand M, Shorowordi KM (2009) Morphology and properties of electrodeposited Zn -Ni alloy coatings on mild steel. J Mech Eng 40:9–12

Ashiru OA, Shirokoff J (1996) Electrodeposition and characterization of tin-zinc alloy coatings. J Appl Surf Sci 103:159–169

Hu CC, Wang CK, Lee GL (2006) Composition control of tin-zinc deposits using experimental strategies. Electrochimical Acta 51:3692–3698

Popoola API, Pityana SL, Popoola OM (2011) Quantitative Study of the Hardness Property of Laser Surface Alloyed Aluminium AA1200. J S Afri Inst Min Metall 111:335–344

Sun G, Zhang Y, Liu C, Luo K, Tao X, Li P (2010) Microstructure and wear resistance enhancement of cast steel rolls by laser surface alloying NiCr-Cr2C2. Mater Des 31:2737–2744

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fatoba, O.S., Popoola, A.P.I., Fedotova, T. et al. Electrochemical Studies on the Corrosion Behaviour of Laser Alloyed Zn-Sn Coatings on UNS G10150 Steel in 1M HCl Solution. Silicon 7, 357–369 (2015). https://doi.org/10.1007/s12633-015-9319-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-015-9319-2