Abstract

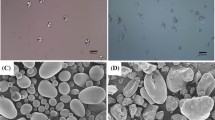

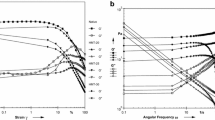

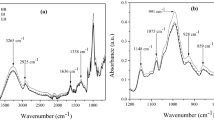

Rice starch–water suspension (20%) were subjected to high hydrostatic pressure (HHP) treatment at 120, 240, 360, 480, and 600 MPa for 30 min. Polarizing light microscope, scanning electron microscopy (SEM), rapid visco analyzer (RVA), differential scanning calorimeter (DSC), and X-ray diffraction were used to investigate the physicochemical and structural changes of starch. Microscopy studies showed that the treatment of starch with HHP under 600 MPa for 30 min resulted in a complete loss of birefringence and a gel-like appearance. The treatment of starch suspension with HHP at 600 MPa resulted in a significant increase in swelling power and solubility at low temperature (50–60 °C), but opposite trends were found at high temperature (70–90 °C). The DSC analysis showed a decrease in gelatinization temperatures and gelatinization enthalpy with increase of pressure levels. RVA viscograms of starches exhibited an increase in peak, trough, and final viscosities, peak time, and pasting temperature but decrease of breakdown, setback viscosities, and pasting temperature when pressure was increased. X-ray diffraction studies showed that the HHP treatment converted rice starch that displayed the A-type X-ray patterns to the B-type-like pattern. These results showed that the treatment of rice starch in 20% starch/water suspension at a pressure of 600 MPa for 30 min led to a complete gelatinization of starch granules.

Similar content being viewed by others

References

Ahmed, J., Ramaswamy, H. S., Ayad, A., Alli, I., & Alvarez, P. (2007). Effect of high-pressure treatment on rheological, thermal and structural changes in Basmati rice flour slurry. Journal of Cereal Science, 46, 148–156.

Bauer, B. A., & Knorr, D. (2005). The impact of pressure, temperature and treatment time on starches: pressure-induced starch gelatinization as pressure time temperature indicator for high hydrostatic pressure processing. Journal of Food Engineering, 68, 329–334.

Błaszczak, W., Fornal, J., Valverde, S., & Garrido, L. (2005a). Pressure-induced changes in the structure of corn starches with different amylose content. Carbohydrate Polymers, 61, 132–140.

Błaszczak, W., Valverde, S., & Fornal, J. (2005b). Effect of high pressure on the structure of potato starch. Carbohydrate Polymers, 59, 377–383.

Buckow, R., Jankowiak, L., Knorr, D., & Versteeg, C. (2009). Pressure–temperature phase diagrams of maize starches with different amylose contents. Journal of Agricultural and Food Chemistry, 57, 11510–11516.

Choi, H. S., Kim, H. S., Park, C. S., Kim, B. Y., & Baik, M. Y. (2009). Ultra high pressure (UHP)-assisted acetylation of corn starch. Carbohydrate Polymers, 78, 862–868.

Douzals, J. P., Perrier-Cornet, J. M., Gervais, P., & Coquille, J. C. (1998). High-pressure gelatinization of wheat starch and properties of pressure-induced gels. Journal of Agricultural and Food Chemistry, 46, 4824–4829.

Jane, J., Wong, K. S., & McPherson, A. E. (1997). Branch-structure difference in starches of A- and B-type X-ray patterns revealed by their Naegeli dextrins. Carbohydrate Research, 300, 219–227.

Katopo, H., Song, Y., & Jane, J. L. (2002). Effect and mechanism of ultrahigh hydrostatic pressure on the structure and properties of starches. Carbohydrate Polymers, 47, 233–244.

Kaur, A., Singh, N., Ezekiel, R., & Sodhhi, N. S. (2009). Properties of starches separated from potatoes stored under different conditions. Food Chemistry, 114, 1396–1404.

Kawai, K., Fukami, K., & Yamamoto, K. (2007). State diagram of potato starch–water mixtures treated with high hydrostatic pressure. Carbohydrate Polymers, 67, 530–535.

Kim, H. S., Choi, H. S., Kim, B. Y., & Baik, M. Y. (2010). Characterization of acetylated corn starch prepared under ultrahigh pressure (UHP). Journal of Agricultural and Food Chemistry, 58, 3573–3579.

Li, W. H., Shu, C., Zhang, P. L., & Shen, Q. (2010). Properties of starch separated from ten mung bean varieties and seeds processing characteristics. Food and Bioprocess Technology. doi:10.1007/s11947-010-0421-6.

Li, W. H., Zhang, F. S., Liu, P. L., Bai, Y. F., Gao, L., & Shen, Q. (2011). Effect of high hydrostatic pressure on physicochemical, thermal and morphological properties of mung bean (Vigna radiata L.) starch. Journal of Food Engineering, 103, 388–393.

Liu, Y. T., Selomulyo, V. O., & Zhou, W. B. (2008). Effect of high pressure on some physicochemical properties of several native starches. Journal of Food Engineering, 88, 126–136.

Liu, H. S., Yu, L., Dean, K., Simon, G., Petinakis, E., & Chen, L. (2009). Starch gelatinization under pressure studied by high pressure DSC. Carbohydrate Polymers, 75, 395–400.

Mandala, I. G., & Bayas, E. (2004). Xanthan effect on swelling, solubility and viscosity of wheat starch dispersions. Food Hydrocolloids, 18, 191–201.

Oh, H. E., Hemar, Y., Anema, S. G., Wong, M., & Pinder, D. N. (2008). Effect of high pressure treatment on normal rice and waxy rice starch-in-water suspensions. Carbohydrate Polymers, 73, 332–343.

Rubens, P., Snauwaert, J., Heremans, K., & Stute, R. (1999). In situ observation of pressure-induced gelation of starches studied with FTIR in the diamond anvil cell. Carbohydrate Polymers, 39, 231–235.

Sandhya Rani, M. R., & Bhattacharya, K. R. (1995). Rheology of rice flour pastes: relationship of paste breakdown to rice quality, and a simplified Brabender viscograph test. Journal of Texture Studies, 26, 587–598.

Singh, N., & Kaur, L. (2004). Morphological, thermal, rheological and retrogradation properties of starch fractions varying in granule size. Journal of the Science of Food and Agriculture, 84, 1241–1252.

Sodhi, N. S., & Singh, N. (2003). Morphological, thermal and rheological properties of starches separated from rice cultivars grown in India. Food Chemistry, 80, 99–108.

Stolt, M., Stoforos, N. G., Taoukis, P. S., & Autio, K. (1999). Evaluation and modeling of rheological properties of high pressure treated waxy maize starch dispersions. Journal of Food Engineering, 40, 293–298.

Stolt, M., Oinonen, S., & Autio, K. (2001). Effect of high pressure on the physical properties of barley starch. Innovative Food Science & Emerging Technologies, 1, 167–175.

Stute, R., Klingler, R. W., Boguslawski, S., Eshtiaghi, M. N., & Knorr, D. (1996). Effects of high pressures treatment on starches. Starch/stärke, 48, 399–408.

Tsai, M. L., Li, C. F., & Lii, C. Y. (1997). Effects of granular structures on the pasting behaviors of starches. Cereal Chemistry, 74, 750–757.

Vallons, K. J. R., & Arendt, E. K. (2009a). Effects of high pressure and temperature on buckwheat starch characteristics. European Food Research and Technology, 230, 343–351.

Vallons, K. J. R., & Arendt, E. K. (2009b). Effects of high pressure and temperature on the structural and rheological properties of sorghum starch. Innovative Food Science & Emerging Technologies, 10, 449–456.

Vallons, K. J. R., & Arendt, E. K. (2010). Understanding high pressure-induced changes in wheat flour–water suspensions using starch–gluten mixtures as model systems. Food Research International, 43, 893–901.

Vittadini, E., Carini, E., Chiavaro, E., Rovere, P., & Barbanti, D. (2008). High pressure-induced tapioca starch gels: physico-chemical characterization and stability. European Food Research and Technology, 226, 889–896.

Yu, S. F., Ma, Y., Menager, L., & Sun, D. W. (2010). Physicochemical properties of starch and flour from different rice cultivars. Food and Bioprocess Technology. doi:10.1007/s11947-010-0330-8.

Zaidul, I. S. M., Yamauchi, H., Kim, S. J., Hashimoto, N., Noda, T., Bodson, B., et al. (2007). RVA study of mixtures of wheat flour and potato starches with different phosphorus contents. Food Chemistry, 102, 1105–1111.

Acknowledgments

This work was funded by the Key Technologies R&D Program of China (2006BAD02B01). We also thank the Center for Physical and Chemical Analysis of Beijing Forestry University Technology for utilizing the X-ray diffractometer and scanning electron microscopy.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, W., Bai, Y., Mousaa, S.A.S. et al. Effect of High Hydrostatic Pressure on Physicochemical and Structural Properties of Rice Starch. Food Bioprocess Technol 5, 2233–2241 (2012). https://doi.org/10.1007/s11947-011-0542-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-011-0542-6